In today’s fast-changing world, sustainability is important for manufacturers. They want to make their processes more efficient and eco-friendly. More industries are using sustainable practices. A few key trends show how manufacturing is moving toward a greener future.

Manufacturers are using new methods to reduce waste and improve their environmental impact. They are remanufacturing products and using artificial intelligence. These changes help them keep high-quality production. In this article, we’ll explore some of these major trends and how they are shaping the future of sustainable manufacturing.

Remanufacturing for Maximum Efficiency

Remanufacturing is one of the most exciting trends in sustainable manufacturing today. It is not the same as recycling, repairing, or refurbishing.

Remanufacturing means taking a used product and taking it apart. Then, it is restored to like-new condition and sold again. You can apply this process to a wide range of products, from car parts to office furniture.

Some industries that are leading the way in remanufacturing include:

- – Aerospace

- – Automotive

- – Consumer Products

- – Electrical Equipment

- – Heavy Duty Equipment

- – Medical Equipment

- – Restaurant Equipment

For example, in the automotive industry, remanufacturing auto parts helps reduce waste and inefficiency. Rather than producing new parts from scratch, manufacturers take old components, refurbish them, and either reuse them or repurpose the materials. This process saves on raw materials and cuts down on production costs.

Additionally, remanufactured products often have market value that is similar to new products. This makes remanufacturing a smart choice for businesses aiming to cut costs, minimize waste, and remain competitive. By extending the life cycle of products, remanufacturing also helps reduce the overall environmental footprint of the manufacturing industry.

Sustainable Practices in Manufacturing

Another important trend in sustainable manufacturing is the adoption of eco-friendly practices to minimize energy consumption and reduce emissions. Manufacturers are upgrading equipment, optimizing processes, and adopting renewable energy sources such as solar or wind power to run their operations more efficiently.

Governments and regulatory bodies have introduced incentives for companies that commit to sustainability. These can come in the form of tax credits, grants, or reduced fees, making it easier for manufacturers to adopt green practices.

One of the biggest opportunities for improvement in sustainability involves reducing Scope 3 emissions. While companies can directly control their Scope 1 and 2 emissions (such as emissions from their facilities and energy consumption), Scope 3 emissions come from their supply chain, including the extraction, production, and transportation of raw materials. According to studies, up to 70% of a manufacturer’s emissions come from Scope 3 activities, so addressing this is key to truly reducing their environmental impact.

Energy Management Systems and Industry 4.0

The integration of technology in sustainable manufacturing, particularly through energy management systems (EMS), is another exciting trend. An EMS helps manufacturers monitor and control their energy usage in real-time, making it possible to dynamically adjust energy flows to maximize efficiency.

The concept of Industry 4.0—the smart use of technology like sensors and artificial intelligence (AI) in manufacturing—also ties into sustainability. By incorporating smart technology into factories, manufacturers can fine-tune their energy usage, automate processes, and monitor environmental conditions more efficiently. For example, AI can optimize HVAC (Heating, Ventilation, and Air Conditioning) systems by adjusting settings based on air quality, humidity, and temperature, which leads to significant energy savings.

The combination of EMS and Industry 4.0 sensors has led to efficiency improvements of up to 16% in some manufacturing facilities, all while reducing costs by 15%. As more factories embrace these technologies, we will see even greater gains in sustainability across the sector.

Reducing Waste and Emissions

Waste reduction has always been a goal in manufacturing, but it is now becoming even more important as companies focus on sustainability. Manufacturers are conducting energy audits to identify areas where they can cut energy consumption, upgrade equipment, and implement energy-saving measures.

In addition to reducing energy usage, waste reduction often involves implementing better control systems and optimizing production processes to minimize material waste. By doing so, manufacturers can produce high-quality products while significantly reducing their environmental footprint.

Sustainable Logistics

Sustainable logistics, also known as green logistics, refers to the practices manufacturers and suppliers use to minimize the environmental impact of moving goods through the supply chain. This includes everything from processing raw materials to delivering the final product to consumers.

Some ways that companies are embracing sustainable logistics include:

- – Using renewable energy for transportation and production.

- – Planning more efficient routes to reduce fuel consumption.

- – Extending the life expectancy of transportation vehicles by maintaining equipment more effectively.

- – Going paperless, which reduces waste and reliance on non-renewable resources.

Incorporating sustainable logistics practices not only lowers emissions but also aligns companies with growing regulations on sustainability. Many consumers now expect the companies they buy from to take social and environmental responsibility seriously, which means adopting green practices can improve customer relations and brand image.

Moreover, when manufacturers locate near each other within the same industrial park, they can reduce transportation and logistics costs by delivering products next door instead of shipping them across the country. This kind of collaboration fosters a more sustainable supply chain and further cuts down on emissions and transportation-related waste.

The Role of Artificial Intelligence

Artificial intelligence is becoming an increasingly valuable tool for manufacturers looking to go green. AI can help companies make real-time decisions based on data gathered from IoT (Internet of Things) devices, production lines, and energy management systems. By analyzing this data, manufacturers can identify inefficiencies in their processes and adjust them instantly, leading to more sustainable operations.

For example, AI can optimize energy use by predicting when machines will need to operate and shutting them down during periods of inactivity. AI systems can also analyze data on material usage to help reduce waste and streamline supply chains.

Additionally, AI can improve production planning by predicting demand and adjusting manufacturing schedules accordingly. This reduces overproduction, which is a major source of waste in many industries. As AI continues to evolve, it will play a crucial role in helping manufacturers meet their sustainability goals.

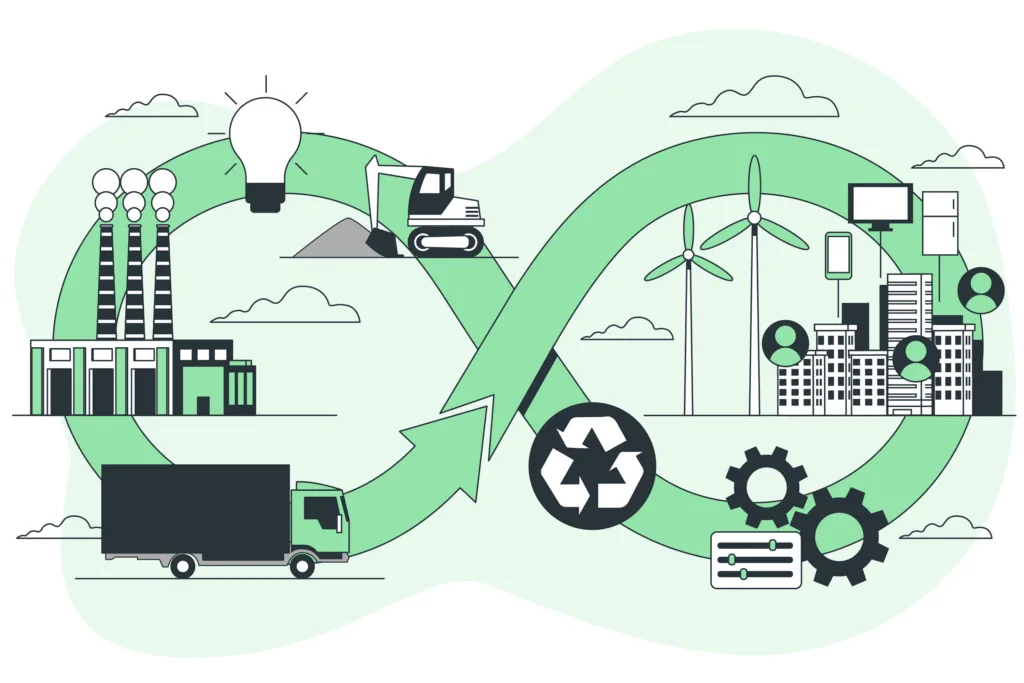

Sustainable manufacturing is quickly becoming the standard, with companies embracing everything from remanufacturing to green logistics and AI-driven energy management systems. By adopting these practices, manufacturers can not only reduce their environmental impact but also cut costs and remain competitive in a rapidly changing market.

As we look to the future, the continued integration of technology, smarter energy management, and circular economy models will be key to making manufacturing more sustainable and efficient. For companies that embrace these trends, the benefits will be significant—not only for their bottom line but for the planet as well.

If you liked reading this article, we recommend the following content:

The Power of Circular Economies in Automotive Manufacturing